Guardian Monitoring®

Connect Transformer Monitoring to Intelligent Decision Making

SDMyers combines the latest in single- and multi-gas monitoring hardware and software with proactive diagnostic expertise. Monitor the health of your equipment with exponentially more data than standard routine oil testing. And, when connected with Transformer Dashboard's trend analysis and graphing, you can plan transformer maintenance and reduce your risk of transformer failure. For a comparison of our 1-, 5-, and 9-gas monitors and their analytical capabilities, download the whitepaper.

All of our gas monitors work around the clock to provide you with data that is accurate beyond industry standards.

The monitor sends that data to your Transformer Dashboard® and to our engineering team, and any deviation from the norm is flagged for review.

If our engineers determine there is an imminent threat to your system, we provide clear options and a realistic plan on what to do next—and no false alarms.

Armed with detailed data and insight from SDMyers, you’ll know what steps to take to keep your operation running with the least amount of downtime possible.

Single-gas monitor (G1)

Single-gas monitors detect hydrogen (H2) levels in transformer oil. Virtually maintenance free and designed for rugged industrial environments. Solid-state technology that detects hydrogen levels to industry standards. Instant connectivity to Transformer Dashboard®.

5-gas monitor (G5)

This five-gas monitor’s capability to detect methane, ethylene, and acetylene allows us to use industry-standard analytical tools to diagnose faults. Nondispersive Infrared technology for reliable measurements. Modular design allows for future upgrades and component maintenance. No consumables, such as calibration or carrier gases. Instant connectivity to Transformer Dashboard®.

9-gas monitor (G9)

A nine-gas monitor samples and measures all gases that are needed for a full Dissolved Gas Analysis and provides information on specific sub-faults. Full DGA monitoring for deep insight into your transformer’s health. Modular design allows for future upgrades and component maintenance. No consumables such as calibration or carrier gases. Market-leading photoacoustic spectroscopy technology in terms of accuracy and durability. Instant connectivity to Transformer Dashboard®.

five decades of reliability expertise

With more than 50 years of transformer management experience, we focus on keeping your transformer running so you can stay focused on what you do best—maintaining and improving your entire operation.

From help selecting the monitor that best fits your needs, to setting alarm parameters appropriate for each transformer, through close monitoring of those levels to keep your equipment running, day in, day out… we’ve got this.

Avoid COSTLY false alarms

We know that every transformer is unique. Our engineers use an alarm philosophy that accounts for the transformer’s manufacturer, model, history, application, and age. We set alarm parameters so that we alert you only when there’s an issue that needs your attention. No more, no less.

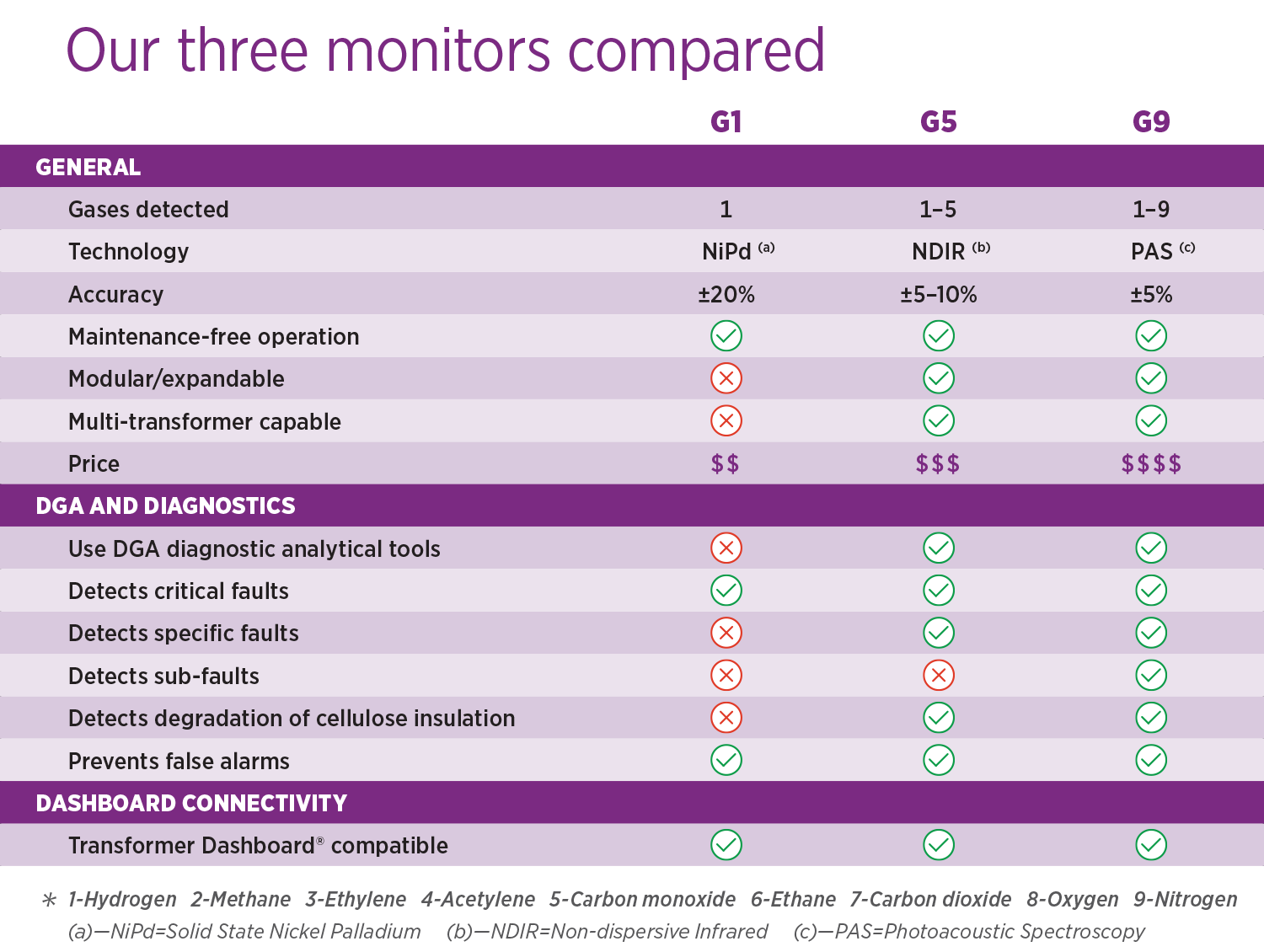

our three monitors compared

For a detailed comparison of the G1, G5, and G9 monitors we offer as part of the Guardian Monitoring Service, and for information on the analytic capabilities of these technologies, download the whitepaper.

1-Gas Monitor

alerts on critical transformer faults

Hydrogen accompanies most known transformer faults, which makes this single-gas monitor an excellent indicator when there is an issue developing inside your transformer. If the monitor detects a significant spike in H2, the specifics of the fault can then be determined with a full Dissolved Gas Analysis profile and an array of chemical, mechanical, and electrical testing to reveal the specifics of the fault.

- Virtually maintenance free and designed for rugged industrial environments

- Solid-state technology that detects hydrogen levels to industry standards

- Instant connectivity to Transformer Dashboard®

5-Gas Monitor

Diagnose critical transformer faults as they happen

This five-gas monitor’s capability to detect methane, ethylene, and acetylene allows us to use industry-standard analytical tools to diagnose faults. Hydrogen is an essential component of any monitoring system because H2 accompanies most transformer faults. Carbon monoxide can indicate degradation of the paper insulation.

- Nondispersive infrared technology for accurate measurements without consumable gases

- Modular design allows for future upgrades and component maintenance

- Cellular communication that is secure, dependable, and reliable

- Instant connectivity to Transformer Dashboard® and other management software

9-gas monitor

Utility-grade DGA technology for mission-critical transformers

A nine-gas monitor samples and measures all gases that are needed for a full DGA and provides information on specific sub-faults. Elevated levels of carbon monoxide and carbon dioxide are indicators of cellulose degradation. High levels of oxygen can accelerate the oxidation and decomposition of paper insulation. This monitor imparts a full DGA profile of the gases inside the transformer at a high frequency, which offers more data for trend analysis.

- Full DGA monitoring for deep insight into your transformer’s health

- Modular design allows for future upgrades and component maintenance

- No consumables such as calibration or carrier gases

- Market-leading photoacoustic spectroscopy technology in terms of accuracy and durability

- Cellular communication that is secure, dependable, and reliable

- Instant connectivity to Transformer Dashboard® and other management software

Please wait while logging in.

Please wait while logging in.